Extracting IIoT Value at the Edge

Guest blog by Greenwave’s Artur Menzeleev

Internet of Things (IoT) edge analytics is experiencing a dramatic upsurge in interest. The impact of moving analytics to the edge is showing its potential in industrial automation, industrial asset optimization, and industrial IoT (IIoT) deployments. As both hardware processing and software analytics get more powerful at the edge, the industry has begun shifting the traditional analytics-to-action loop away from the cloud and out to the edge of “things”: gateways and devices. True edge device intelligence has long been a driving ambition for M2M system designers and developers of IoT solutions: It just took a while for Moore’s Law to make it feasible on a widespread basis.

Edge Analytics Must Be Small

Even though we have the potential to make everything from our TVs to our lightbulbs “smart,” this does not mean edge device intelligence is anywhere near standard. The most current IoT/IIoT implementations are still cloud-powered. This is because, no matter what kind of analytics functions you want to perform at the edge, you have a strong chance of running into processing resource and power constraints. The smaller the device, the greater the chance of limited resources dedicated to fulfilling its primary function (for example, the purpose of a lightbulb is to reliably provide light, not to collect interesting usage data or to leverage that data to optimize bulb life or energy consumption). By nature, edge devices are never going to have a lot of extra space or RAM or CPU. Thus, the central challenge of bringing intelligence to the edge is striking the right balance between capabilities and resource usage of the analytics engine.

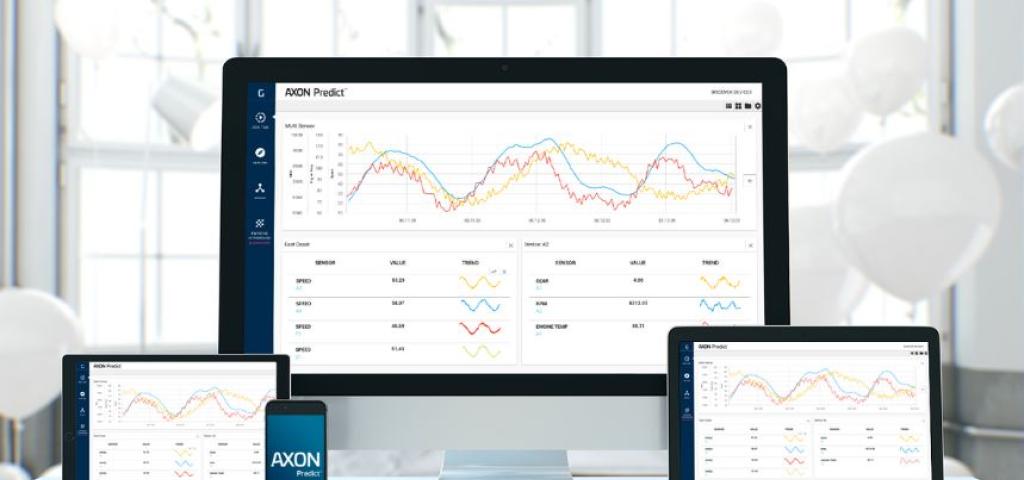

Many software players in the IoT space have taken their original analytics platforms and tried to shrink them down to “fit” edge constraints, with limited success. You can’t starve a Mastiff to get a Greyhound. Edge analytics engines must be purpose-built to function natively on edge devices, as is the case with AXON Predict™.

Edge Analytics Must Be Fast

If you’re running on the edge, you want to be able to act in “real time” (which could mean subseconds, seconds, or minutes depending on the application). The classic example is the autonomous vehicle, where instantaneous responsiveness is a life-and-death matter. But even less-critical edge computing applications benefit from reduced data flow to/from the cloud, and potential freedom from the requirement for constant cloud connectivity. A key value of edge computing is rapid and autonomous response “on the ground.” If you have enough data to make a decision at the edge, you want to be able to process it there and then to make that decision.

Edge Analytics Must Be Powerful

While the wonders of edge analytics are commonly personified in self-driving cars or autonomous drones, use cases don’t have to be that ambitious to be incredibly powerful. Anomaly detection and predictive maintenance are straightforward examples of extremely useful IIoT edge computing applications in industrial automation and industrial asset optimization. An embedded engine that detects impending equipment failure or even suboptimal functioning and generates appropriate alerts, actions, or directives can be invaluable in numerous contexts. Consider devices that are expensive, difficult to maintain, and generally disconnected from the cloud: drills on oil rigs, wind turbines, cranes, trucks, conveyers, etc. For these complex, disconnected devices, edge analytics proves its worth exponentially. As noted in a recent TNW article on IIoT: “Maintenance done at the right time reduces costs. After all, fix something too late and it’s broken again quicker; fix something too early and the costs of maintenance were unnecessary. For example, regular preventative maintenance on a 10-year-old air compressor worth $32,900 can extend the machine’s life for up to four years, resulting in a total savings of up to $6,359.” And that’s just one piece of equipment.

Edge analytics enables modern predictive maintenance, even for far flung assets devoid of constant cloud connectivity. There are countless other industrial applications and use cases for the technology, which will continue to drive optimization innovation for IIoT applications far into the future.